Press plant and laser beam cutting

Our location in Lehrensteinsfeld specializes in the production of high-quality pressed and stamped parts. In our press shop parts are produced for all industries. Our own trapezoidal blanks are used here.

Our location in Lehrensteinsfeld specializes in the production of high-quality pressed and stamped parts. In our press shop parts are produced for all industries. Our own trapezoidal blanks are used here.

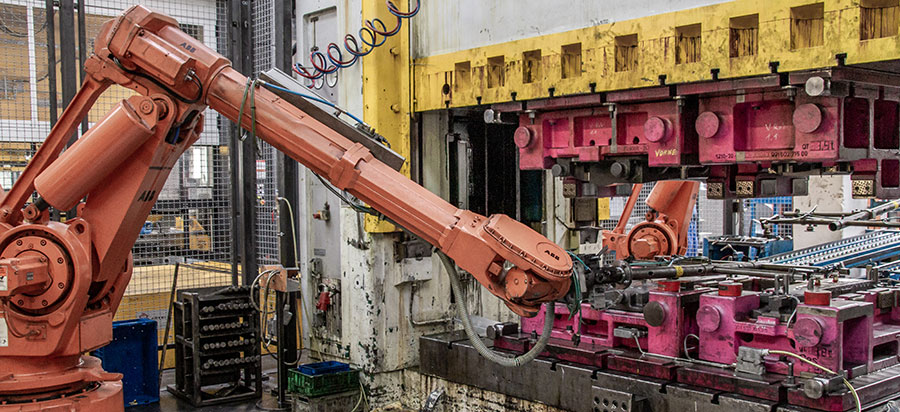

Pressed parts production

Our pressed parts are produced using line tools on hydraulic and mechanical large presses. Two press lines are connected to each other by robots and can produce parts of different sizes. Our largest press has a press capacity of 1200 tons, while more delicate parts are manufactured on our small manual presses. Our presses are up to 3600 mm wide and have die cushion and slide cushion functions. For this procedure we work with boards that are produced from coils.

Stamping parts production

We are able to manufacture individual stamped parts using various stamping, follow-on composite and transfer tools on our stamping and servo transfer presses. Our largest servo transfer press has a pressing force of 1000 tons and a stroke frequency of 60 per minute – the table size is 4000 x 2000 mm. The stamped parts are produced with coils made of steel, aluminum and stainless steel. Large parts and those with special surface requirements are de-stacked by hand. A shorter cycle time is used for the production of bulk material.

Production of circuit boards

Be it trapezoidal, rectangular or parallelogram-shaped, we can manufacture blanks in various shapes on our own blank cutting machine. Upon request, we can design very small widths or feeds but high part volumes are also possible because of our innovative lightweight swivel unit (ILSe). Steel, aluminum or stainless-steel blanks are created from the coil and are then sent to you on one-way or returnable pallets. We also use the blanks that we produce for our in-house pressed parts production.

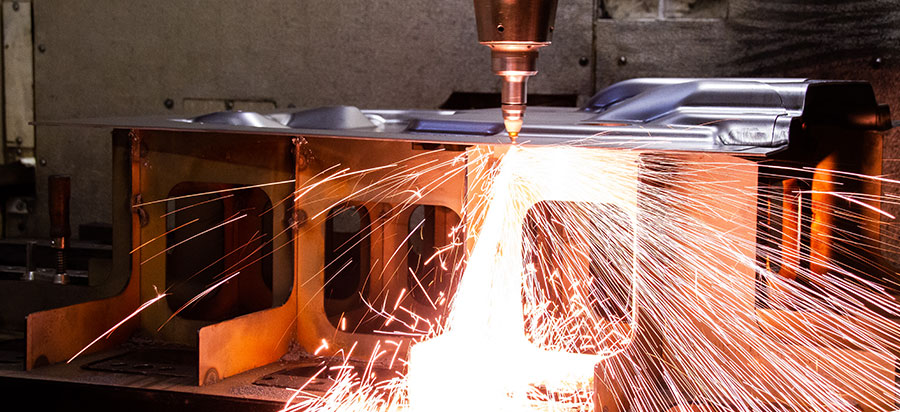

Laser cutting

Laser cutting is used when only small quantities are required or parts with a wide range of versions are manufactured. There is no need, therefore, for investment in expensive trimming tools. Our 5-axis laser system is used primarily for 3D trimming, but can also create 2D contours. Drawn parts that were manufactured in the press plant are, for example, cut using lasers instead of tools on the component contours.

Washing

We clean surfaces of every type using alkaline and acid cleaner We use different cleaning agents and media for this. The conversion coating is retained. We can wash parts up to 1.5 m in size on our systems.