Surface hardness technology

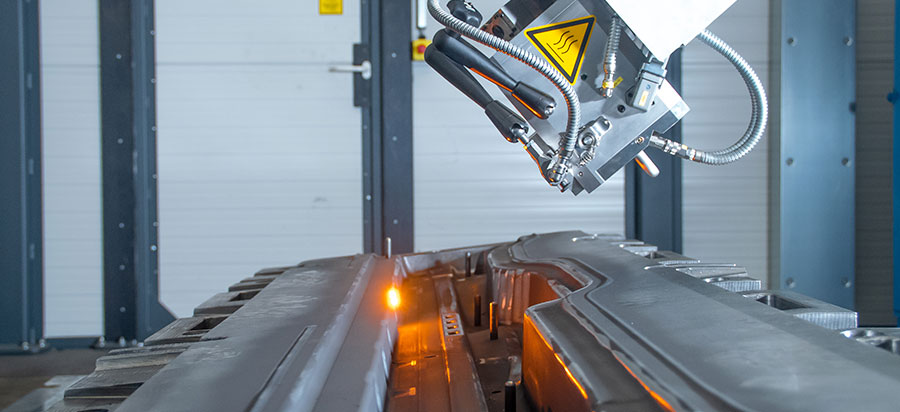

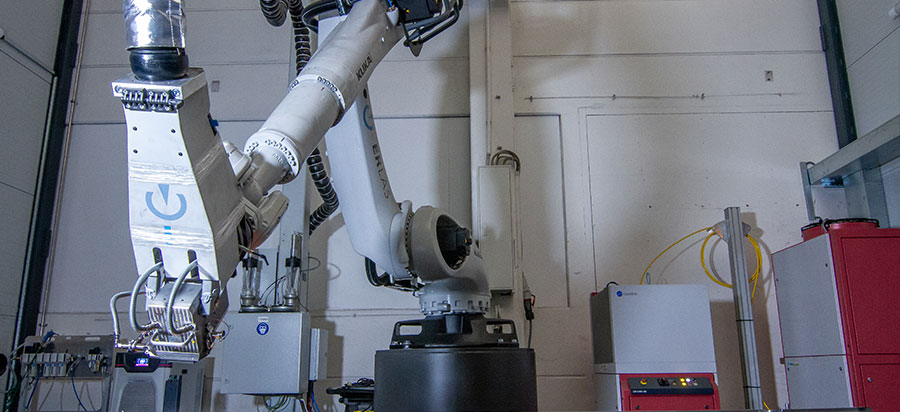

The properties of surfaces are diverse. For several years we have been specializing in surface hardening. In this process we heat the surface of heavily contaminated material and thus obtain a modified material structure with a harder, more wear-resistant surface. The process is used to prevent the core from becoming tough and brittle. It stays soft instead. To reduce thermal distortion, we only partially harden on the contaminated surfaces. For the process, we use the laser beam and the induction hardening, mainly in injection molding tools in mold and die construction and in tool making. Here the introduction of heat into the materials is far less in laser hardening than in induction hardening. As a result, less distortion is likely with laser hardening. We also offer laser beam cladding as a repair solution, as well as with contour changes on a wide range of parts.

Components and areas of the injection molding tools include separating edges, sprue areas as well as sliders and guides. In sheet metal forming, this includes cutting edges and active radii and surfaces. The processes are also used for numerous other parts and industries.